Researchers at Linköping University in Sweden have made significant strides in enhancing the efficiency of hydrogen production from water, demonstrating that a new three-layer material combination can vastly improve the chemical reaction process. Hydrogen generated from water is increasingly seen as a key renewable energy source, especially when produced via solar energy.

In a bold move, the European Union plans to ban the production of new petrol and diesel cars by 2035, catalyzing the shift towards electric vehicles. However, electric motors are not universally suitable for all modes of transportation. As noted by Jianwu Sun, an associate professor at Linköping University and the lead investigator of the study published in the Journal of the American Chemical Society, traditional passenger vehicles can benefit from battery storage, while heavy trucks, ships, and aircraft may require alternative energy sources. Hydrogen emerges as a promising candidate to fill this gap in clean and renewable energy.

The research team at LiU is dedicated to developing materials that harness sunlight to produce hydrogen gas (H2) from water (H2O). They previously identified cubic silicon carbide (3C-SiC) as an effective material to facilitate the photochemical reaction necessary for splitting water into hydrogen and oxygen. Its ability to capture sunlight proves advantageous for energy conversion during this process.

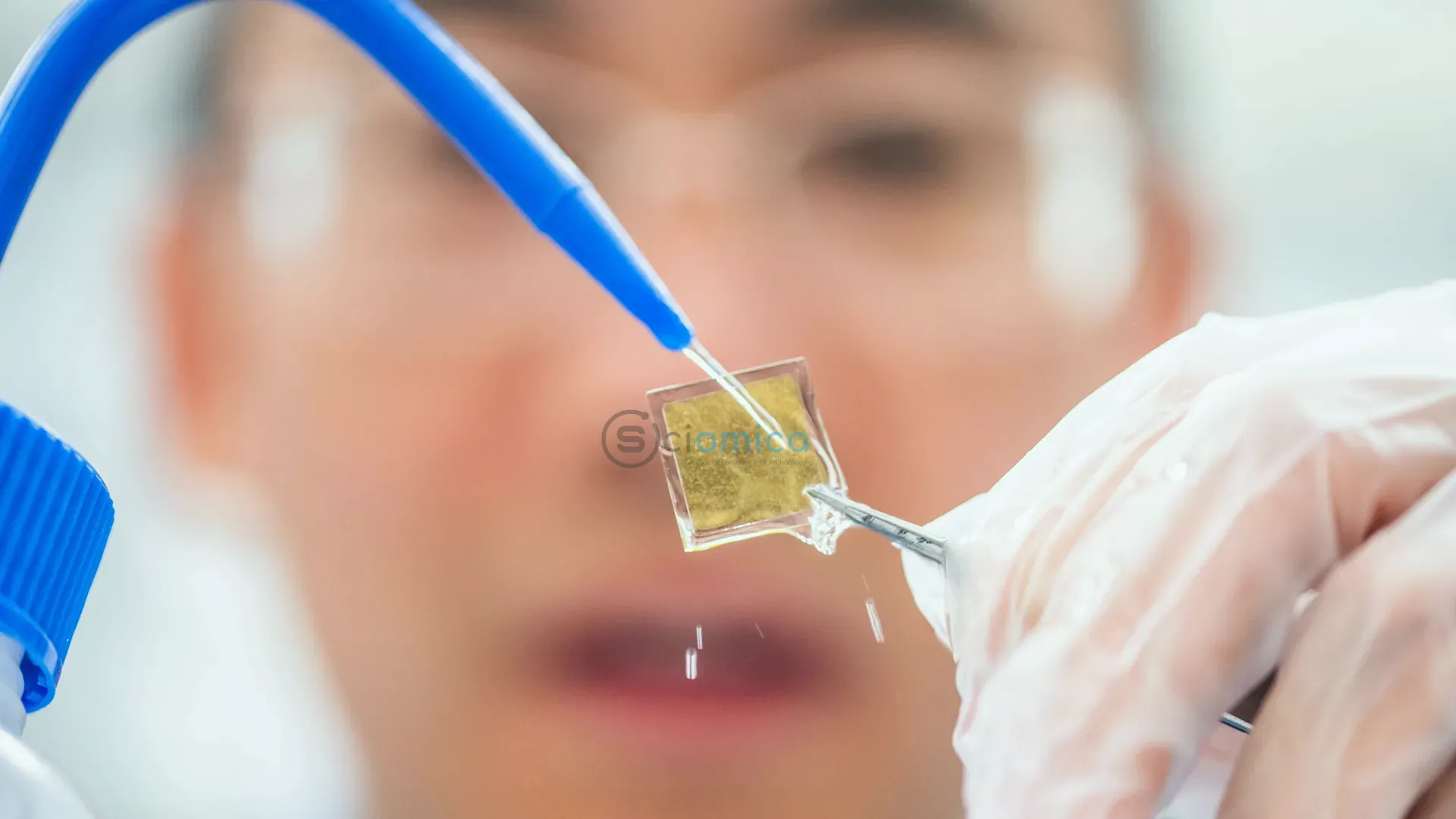

In their latest study, the team has advanced their research with a newly designed material that features a tripartite structure: a base layer of cubic silicon carbide, overlaid with a cobalt oxide layer and a catalytic material that assists in the water-splitting reaction. Sun emphasizes the complexity of this structure and the team’s focus on understanding how each layer contributes to enhancing the material’s overall efficiency. Remarkably, the innovative layered material demonstrates an eightfold increase in performance compared to pure cubic silicon carbide for hydrogen production through water splitting.

As sunlight interacts with this intricate structure, it generates electric charges that work to break down water molecules. One of the major challenges scientists face in this field is preventing the generated positive and negative charges from recombining. The combination of cubic silicon carbide with the cobalt oxide layer and a catalyst enhances the charge separation, making the water-splitting process more efficient.

Currently, hydrogen available in the marketplace is largely “grey,” derived from fossil fuels like natural gas, which contributes significantly to carbon emissions and climate change. In contrast, “green” hydrogen is produced using renewable electricity, presenting a cleaner alternative. The researchers at LiU aim to achieve a method where sunlight drives the entire photochemical reaction, targeting a production efficiency of 10 percent. Current efficiency levels for most materials being developed range between 1 and 3 percent. Jianwu Sun anticipates that it could take five to ten years to reach this goal, which would substantially lower production costs for green hydrogen compared to existing technologies that utilize supplemental renewable electricity.

The research has attracted funding from various organizations, including the Swedish Foundation for International Cooperation in Research and Higher Education (STINT), the Olle Engkvist Stiftelse, the ÅForsk Foundation, and the Carl Tryggers Stiftelse, along with support from the Swedish Government’s Strategic Research Area in Advanced Functional Materials at Linköping University.

Reference:

- Hui Zeng, Satoru Yoshioka, Weimin Wang, Zhongyuan Han, Ivan G. Ivanov, Hongwei Liang, Vanya Darakchieva, Jianwu Sun. Manipulating Electron Structure through Dual-Interface Engineering of 3C-SiC Photoanode for Enhanced Solar Water Splitting. Journal of the American Chemical Society, 2025; 147 (17): 14815 DOI: 10.1021/jacs.5c04005