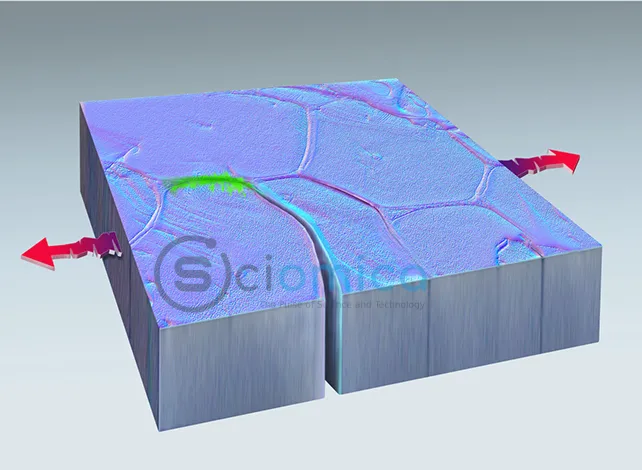

In a remarkable breakthrough in materials science, researchers from Sandia National Laboratories and Texas A&M University have documented a nanoscale self-healing phenomenon in damaged metal. The findings, published in Nature, suggest a new frontier in engineering—especially regarding structures and machinery that succumb to fatigue over time.

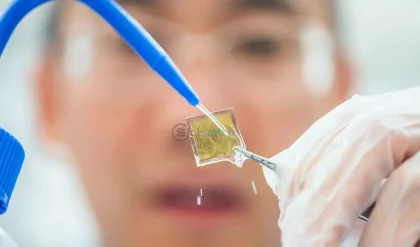

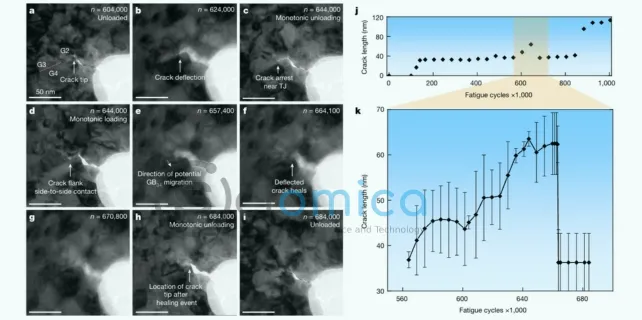

Utilizing a specialized transmission electron microscope to apply strain on a piece of platinum suspended in a vacuum, scientists conducted their experiments by pulling the ends of the metal at a staggering rate of 200 times per second. Under these conditions, they aimed to expose the effects of fatigue damage, which generally leads to microscopic breaks and could jeopardize structural integrity in various machinery and materials.

After approximately 40 minutes of observation, the research team was astonished to see the crack in the 40-nanometer-thick platinum film begin to mend itself before re-initiating a fracture in a different direction.

“This was absolutely stunning to watch firsthand,” commented Brad Boyce, a materials scientist at Sandia National Laboratories. “We certainly weren’t looking for it. What we have confirmed is that metals have their own intrinsic, natural ability to heal themselves, at least in the case of fatigue damage at the nanoscale.”

Boyce and his team caution that while the findings are groundbreaking, they are still in their infancy. The specific mechanisms behind this self-healing property remain undetermined, leaving open questions about practical applications. Nonetheless, if successfully harnessed, self-healing metals could revolutionize fields ranging from civil engineering to consumer electronics, potentially saving enormous amounts of time and resources related to repairs.

This self-healing phenomenon, while unprecedented, is not entirely unforeseen. In a 2013 study, Texas A&M’s Michael Demkowicz predicted such nanoscale healing, noting that tiny crystalline structures within metals can shift in relation to stress, possibly allowing for self-repair.

Demkowicz contributed to the recent study, validating his earlier theories through updated computer simulations that mirrored the observed behavior during experiments. Their analysis offers a glimpse into the atomic-level responses that might explain the crack’s ability to heal.

Significantly, this healing occurred at room temperature, diverging from conventional thought that metals require heating to alter their structure. The implications are substantial, as traditional metalworking techniques often rely on heat treatment. One theory suggests that the phenomenon might relate to cold welding, a process where metals bond through atomic interaction in the absence of air or contaminants, especially in a vacuum.

Demkowicz expressed optimism that these findings would encourage materials researchers to revisit their understanding of how materials can behave under certain conditions. “Under the right circumstances, materials can do things we never expected,” he added.

This research has the potential to reshape materials engineering, leading to innovations that could manifest in everyday applications across numerous industries.

An earlier version of this article was published in July 2023.