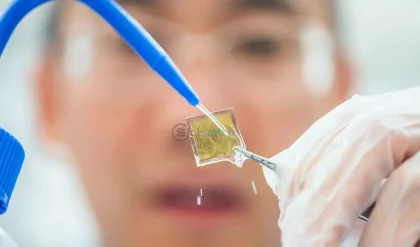

Researchers at Rice University have made a significant breakthrough in the field of electrochemical devices designed to convert carbon dioxide (CO2) into valuable fuels and chemicals. Their findings, published in the prestigious journal Science, reveal a remarkably straightforward method to enhance the stability of these systems, primarily achieved by passing CO2 through an acid bubbler.

The study addresses a longstanding challenge in CO2 reduction systems: the accumulation of salts that block gas flow channels, diminishing efficiency and leading to premature system failures. By adopting a novel technique known as acid-humidified CO2, the researchers have reportedly increased the operational lifespan of CO2 reduction devices by over 50 times, achieving more than 4,500 hours of stable operation in a scaled-up reactor — a remarkable feat in this emerging green technology sector.

Electrochemical CO2 reduction, or CO2RR, harnesses electricity—ideally drawn from renewable sources—to convert the greenhouse gas CO2 into useful products, including carbon monoxide, ethylene, and various alcohols. These outputs can subsequently be processed into fuels or employed in various industrial applications, turning a harmful byproduct of human activity into a valuable resource.

Despite its promise, the practical application of CO2RR has been limited by issues related to system stability. A critical concern is the buildup of potassium bicarbonate salts within gas flow channels. This accumulation occurs when potassium ions migrate from the anolyte through the anion exchange membrane to the cathodic reaction area, leading to undesirable high pH conditions.

Haotian Wang, an associate professor at Rice and the corresponding author of the study, stated, “Salt precipitation obstructs CO2 transport and overwhelms the gas diffusion electrode, which results in performance failure. This typically occurs within a couple of hundred hours, far from what is needed for commercial viability.”

In a bid to address this issue, the research team employed a clever variation of existing techniques. Rather than humidifying the CO2 gas with water, they bubbled the gas through hydrochloric, formic, or acetic acid solutions. The resulting vapor infiltrated the cathodic reaction chamber in trace amounts, altering local chemistry in a beneficial way. Unlike potassium bicarbonate, salts formed with these acids have higher solubility and thus do not crystallize, preventing channel blockage.

The results were striking. When testing a silver catalyst—commonly used for converting CO2 into carbon monoxide—the system functioned stably for over 2,000 hours in a laboratory-scale setup and surpassed 4,500 hours in a larger electrolyzer. In stark contrast, systems utilizing conventional water-humidified CO2 failed after roughly 80 hours due to salt accumulation.

The acid-humidified method has demonstrated effectiveness across various catalyst types, including zinc oxide, copper oxide, and bismuth oxide, which target different CO2RR products. The researchers also confirmed that this approach can scale successfully, maintaining energy efficiency while avoiding salt blockage over extended periods.

Throughout their experiments, the team observed minimal corrosion or damage to the anion exchange membranes, typically susceptible to chloride, by keeping acid concentrations low. Their method also proved compatible with widely used membranes and materials, enhancing its potential for integration into existing systems.

Using custom-built reactors with transparent flow plates, the team was able to visualize salt formation in real time. Under conventional water humidification, salt crystals began to form within 48 hours. In stark contrast, no substantial crystal buildup occurred with acid-humidified CO2, even over hundreds of hours. Any smaller deposits formed were eventually dissolved and carried away from the system.

Co-first author Shaoyun Hao, a postdoctoral research associate at Rice, noted, “The traditional method of water-humidified CO2 can lead to salt formation in the cathode gas flow channels. We hypothesized—and confirmed—that acid vapor could dissolve the salt and convert the low solubility KHCO3 into a salt with higher solubility, thus adjusting the solubility balance to prevent clogging without compromising catalyst performance.”

This groundbreaking work lays the foundation for developing more robust, scalable CO2 electrolyzers—an essential requirement for deploying the technology industrially as part of comprehensive carbon capture and utilization strategies. The simplicity of this approach, requiring only minor modifications to existing humidification setups, positions it for widespread adoption without necessitating costly redesigns.

“This is a significant finding for CO2 electrolysis,” stated Ahmad Elgazzar, co-first author and graduate student at Rice. “Our method tackles a long-standing obstacle with a low-cost and easily implementable solution, paving the way for enhanced commercial viability and sustainability of carbon utilization technologies.”

Support for this research was provided by the Robert A. Welch Foundation, Rice University, the National Science Foundation, and the David and Lucile Packard Foundation.

Reference:

- Shaoyun Hao, Ahmad Elgazzar, Shou-Kun Zhang, Tae-Ung Wi, Feng-Yang Chen, Yuge Feng, Peng Zhu, Haotian Wang. Acid-humidified CO2 gas input for stable electrochemical CO2 reduction reaction. Science, 2025; 388 (6752) DOI: 10.1126/science.adr3834